Why do SUP boards with same size and shape have different weight?

When SUP boards with same size and shape are charged with the same air pressure, why are the boards different in hardness and deformation when standing on?

The reason is that SUP boards use different drop stitch materials.

The following five aspects are explained in detail.

1. Basic structure of drop stitch material

2. Working principle of drop stitch material

3. Internal density of drop stitch material

4. Three commonly used drop stitch materials

5. Precautions when using

1. Basic structure of drop stitch material

The inflatable paddle board is made of drop stitch material, and the interior is covered with numerous tough threads . The upper and lower layers are made of PVC and woven mesh, and the upper and lower layers are combined by high-strength threads in the middle. A certain thickness and shape can become very thin after deflation.

2. Working principle of drop stitch material

When the inside of the board is constantly inflated, the threads will firmly pull the upper and lower layers of PVC material, and the board will maintain a fixed shape so that will not bulge like a balloon. As the pressure continues to increase, the pulling force of the threads gradually increases, and the board becomes harder and harder, which feels solid when pressed by hand. Once the thread is broken, the upper and lower layers of PVC lose their restraint and become “expanded” under high pressure. The pits that are often seen on the surface of the board are the junctions of the threads and the PVC fabric.

3. Internal density of drop stitch material

The drop stitch density is the number of threads per unit area. In the case of the same material, the higher the threads density, the greater the pressure that the board can withstand, which can be directly reflected in the recommended air pressure of the board.

Of course, the higher the density of the threads, is not always the better. The higher the density, the heavier the board. And it’s more inconvenient to store, fold and carry. Therefore, the density and strength of the drop stitch fabric need to reach a balance point. The density of drop stitch fabric usually used is 130-140 pieces/100 square centimeters, which not only ensures sufficient strength, but also does not make the board too heavy.

If the thread is broken at some position, it will cause the board to bulge.

For example, the inflation valve of the inflatable board is installed at the rear, so the internal threads of the inflation valve area is broken, and the board opposite to the inflation valve will bulge. But generally during design, the position of the inflation valve will be placed at the tail of the board, opposite to the fin groove, so that the bulge will not appear in the visible position. And it will not affect the appearance or usage.

4. Three commonly used drop stitch materials

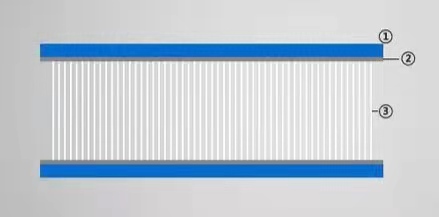

4.1 Single-layer drop stitch material

①PVC ②base fabric ③thread

At present, the most used material on the market is single-layer drop stitch material.

The thickness is about 0.8mm.

Single layer means that a single layer of PVC material is attached to the outside of the fabric, and the liquid PVC is attached to the surface of the fabric like a putty to form a single layer of PVC protective layer. The thickness of the single-layer drop stitch material is generally relatively thin, and air pressure value that can be withstood is low, generally around 12-15psi.

Advantages: light weight, easy to fold and carry.

Disadvantages: easy to deform and lose shape, slightly poor air tightness, low strength and poor durability.

Single-layer materials are mostly used for leisure boards, children’s boards that do not require high strength, and larger team boards or air tracks which need to be easily folded. Although the board of single-layer material is light, it is easy to give people a soft feeling, and it is easy to deform when standing on the board.

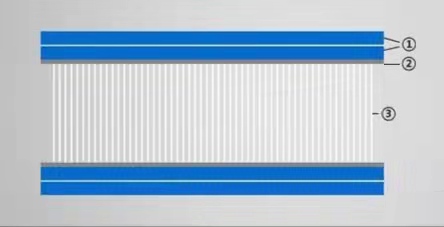

4.2 Double layer material.

①PVC ②base fabric ③thread

The thickness is about 1.3mm.

On the basis of the single-layer material, glue and then paste a layer of PVC manually, the double-layer material will be much thicker than the single-layer. This material can withstand higher air pressure, and the recommended air charge pressure is generally around 15-20psi.

Advantages: high strength, not easy to deform, durable, good air tightness.

Disadvantages: heavy, too thick and difficult to fold and store, prone to defects.

The double-layer material solves the problem of strength, but the extra layer of PVC and the glue used for manual pasting make the board too heavy, and defects such as wrinkles and air bubbles are prone to appear during the pasting process.

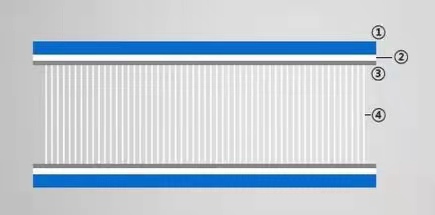

4.3 Lightweight reinforced fusion material, commonly known as reinforced drop stitch material.

①PVC ②adhesive ③base fabric ④thread

The thickness is about 1.8mm.

On the outside of the thread fabric material, a layer of specially formulated adhesive is covered, which acts as a sealing layer and an adhesive layer. Then, by mechanical operation, a layer of high-density PVC is pressed on the surface of the adhesive. In conclusion, the process sounds simple, but it is actually very difficult to control. Due to the mechanical operation, the instability caused by manual operation can be eliminated. Compared with the double layer material, one layer of PVC is reduced, and the use of glue is also reduced, but the adhesive in the middle perfectly enhances the air tightness and strength. Therefore, the lightweight reinforced fusion material can not only achieve the strength and properties close to the double-layer material, but also can reduce the weight well. And the overall surface is also smoother and feels better. But usually it will be more expensive. The recommended air charge pressure is generally around 15-18psi.

Advantages: It is about 20% lighter than the double layer, high strength, rigid, not easy to deform, durable, good air tightness, easy to fold and store, and the board surface is flat and smooth.

Double-layer lightweight reinforced fusion materials are mostly used for racing boards and white water boards which require high strength.

The difference of drop stitch material can be directly reflected in the performance of the board. Under the same air pressure value, the board made of high-strength material is less prone to deformation and bending, and has better rigidity in the case of waves, and has less impact on stability and speed. At higher air pressures that can be tolerated, the performance of the board is even more prominent.

5. Precautions when using

5.1 When using, the inflation pressure should be kept within the recommended air pressure value range. Do not over-pressurize, which will easily lead to threads breakage or deformation.

5.2 Do not keep the board under high air pressure for a long time, it will cause damage to the threads and PVC materials. After a long time, the board will be twisted and deformed, or the curvature (the curvature of the board) will change. This is also the reason why some boards will become more and more warped after a period of use. After use, try to deflate and store it or keep the board at a low air pressure (about 10psi) for storage.

5.3 Avoid exposure to sunlight under high pressure. Especially in summer, exposure to the sun can easily cause the board to deform and burst.